Perhaps one of the biggest changes in the landscape of our industry is the way so many systems companies and fabricators are paying massive attention to flush sash window systems. Much work has been done on the casement side to make improvements on the aesthetic side, but a casement is still a casement. It overlaps the outer frame, it’s a tad bulky in most cases, and you can still only really dress it in colours and wood grain finishes.

It is the flush sash which has provided a true material change in how a PVCu window looks. Flat against the outer frame, it genuinely looks a world different to the casements home owners have been used to for decades. And it is for that reason why it has taken off and rooted with home owners so well. It gives them a proper alternative.

This is why I think the future of PVCu windows lies firmly in flush and timber-look joints.

Driven by looks

The popularity of flush window and timber-look joints is driven purely by it’s looks. A flush window can be reinforced the same way a casement window can. It has the same level of energy efficiency as casements. You can have it double glazed or triple glazed. But the singular, most vital USP that sets it apart from all other PVCu windows is that it is flush. Flat. Smooth. No overlaps. A clean front-on look that casements will never be able to give you.

For customers who are looking for PVCu but something different to the norm, this has become a fantastic alternative. Continuing to have all the benefits of PVCu, with the looks of a smooth, grained profile.

Then you add in the timber-look joints. Yes you can have a welded flush window, but they always look better when you add a mechanical or timber-look joint to them too. Take a look at the featured image above. There can’t be many people who continue to think that casements with v-welds still look better than flush windows with timber-look joints.

The strong and growing demand from home owners is one of the reasons why systems companies and fabricators are investing heavily in flush systems. This is perhaps the clearest and strongest path forwards for the world of PVCu. We have seen almost every single systems house invest heavily and produce their own flush window system. Some better than others. There is most certainly a scale, and I have seen some pretty cheap versions and much higher end ones that are going to do very well in a market where home owners are becoming more prepared to pay more for quality.

Spread to all parts of the market

As with all things new, flush windows are a bit of a leg up from normal casement windows. But, as more of it is sold and more of it is made, that price will come down. And when it does, this is when it will become an option for the lower end of the market to consider.

Although right now flush windows are placed at the higher end of the market, they will eventually spread to all parts of the market, value and higher end alike. Maybe not with all the bells and whistles on, but I can see councils, national installers for house builders, and large contract companies moving to flush in the not too distant future. I’m thinking maybe smooth White, perhaps no timber-look joints, but at least flush and decent U-Values to give homes and new-build estates a face lift.

As is already happening, flush windows will continue to spread in the higher end parts of our market. We’ll see more advancements from systems companies and fabricators as they compete to claim the best flush window system on the market. And we’re going to see the emergence of flush entrance doors and French doors before too long as well. The Residence Collection I believe demonstrated a set of flush French doors at the 2016 FIT Show, assuming my memory serves me right, and they looked pretty good.

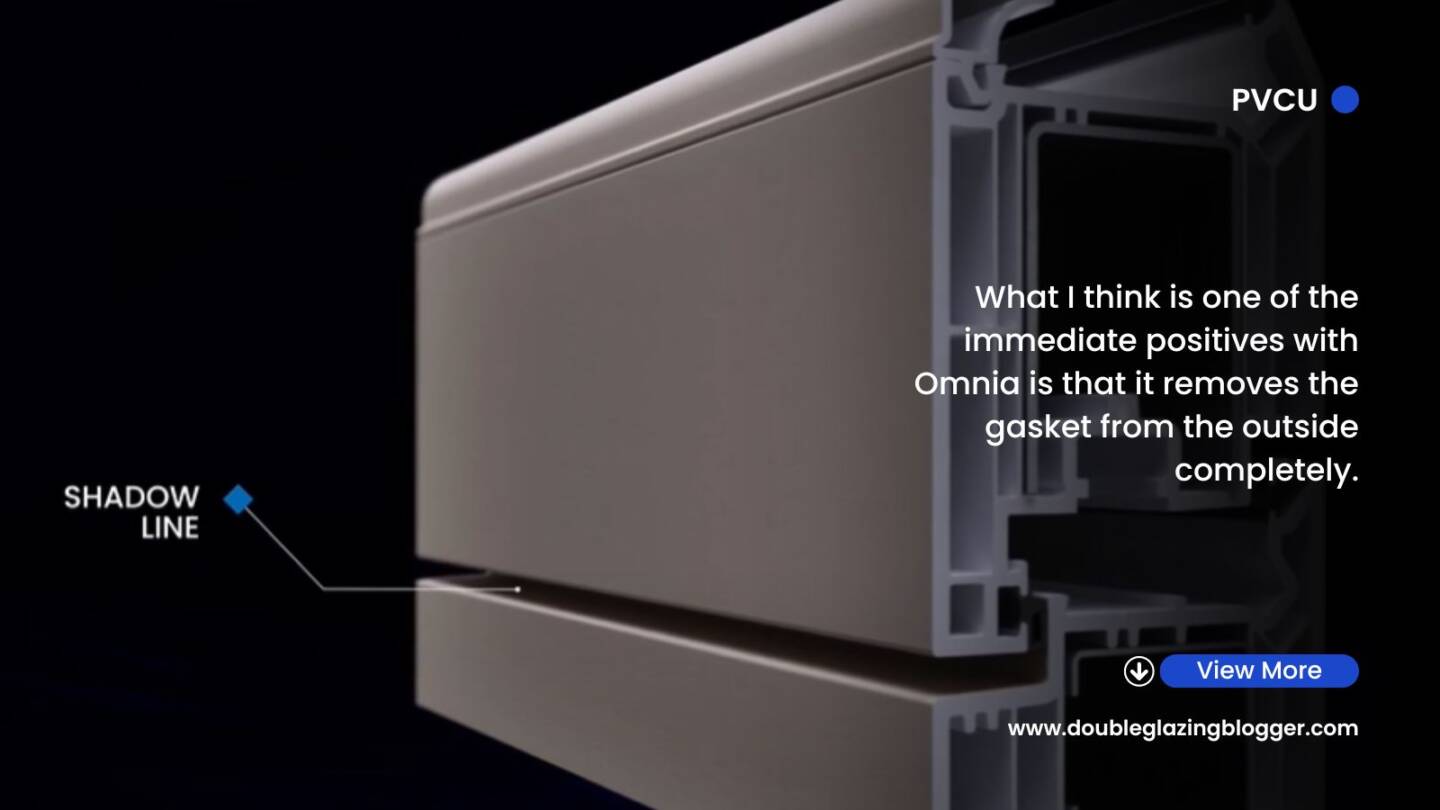

Build quality will be important though. One of the biggest areas that needs to be right with flush windows is weather performance. Unlike normal casement windows which have a double rebate, flush windows rely on a gasket that sits between the sash and the outer frame. That gasket needs to compress well to give good weather performance, without falling out or catching on the frame as you open and close the window. It needs to be long lasting and reliable. If it fails, you’re going to get weather performance problems.

Timber-look joints are going to have to be on the money as well. Now I’m not saying that they all have to be truly mechanically jointed, they can have a weld which makes it look like it’s a mechanical joint. I don’t think home owners are going to be overly bothered about that, so long as it achieves the look they’re after. But from an industry perspective, if it’s going to be mechanically jointed, it needs to be reliable, strong and have a good lifespan. If mechanical joints fail on sashes, the industry is going to have a world of pain in the years down the road.

Poll

Just for fun, I want to know what you think. Do you think this is a flash in the pan? A long term trend? Something that will just blend into the back ground? Before you get on with your day, click an option below and let us know what we think as an industry and where the future of flush and timber-look joints lies.