I think it is fair to say that triple glazing has had a pretty mixed performance over the past ten to fifteen years. Once billed as the next generational change in IGU technology, it has failed to gain the traction some had hoped it would.

Progress for triple-glazed units has been held back by a number of issues, including cost, weight, profile limitations, transport and hardware. Although demand for lower U-Values from homeowners and clients undertaking large renovation projects or self-builds has seen the use of triple glazing increase.

Things might be about to change, however, as two leading IGU producers are about to bring to market new triple-glazed units which may well address a number of those issues just stated. One of which has the backing of US glass and tech giants Corning Incorporated.

Triple glazing 2.0

The two companies in question are Regency Glass and Clayton Glass. Those of you who follow these companies on social media, especially LinkedIn, will have seen both these businesses announce new innovations in the triple glazing space.

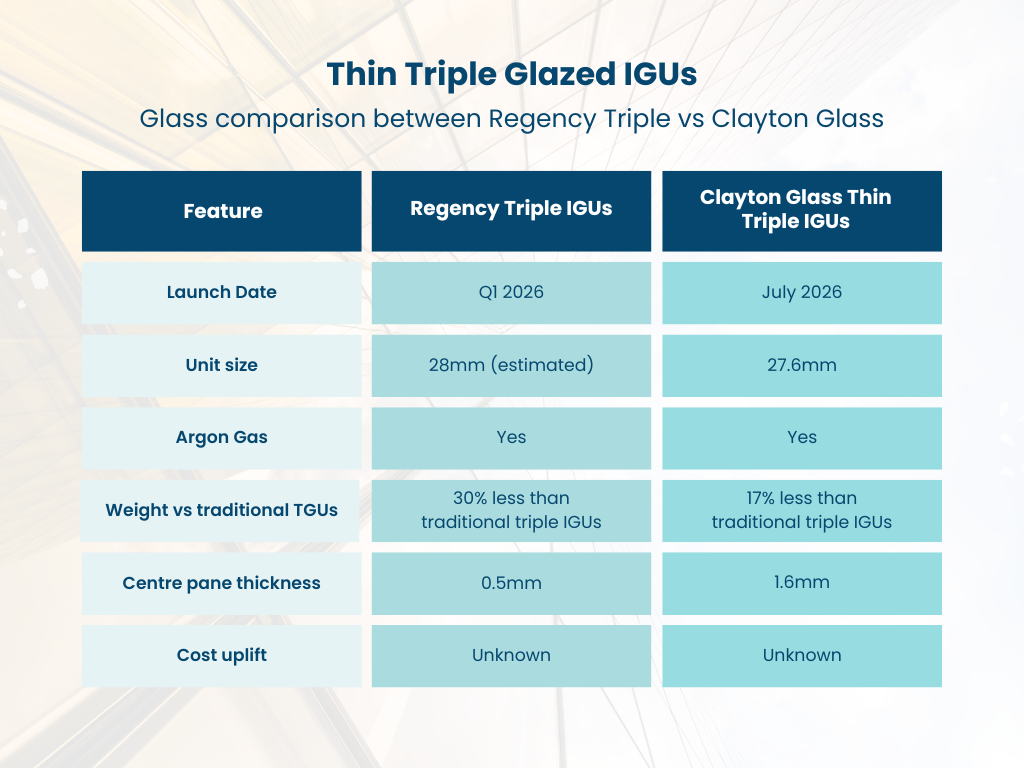

For now, based on a LinkedIn post by Clayton Glass, they are calling theirs Thin Triple IGUs. Regency have branded theirs Regency Triple. There is more information publicly available about the Regency Triple product, with limited information on the Clayton Glass product. But for the sake of communicating what is known as clearly as possible, below is a comparison table to help us understand the differences between the two technologies:

According to the information that is available, Regency Triple is going to be the first to market, with the company saying its product will be available from Q1 2026. That puts it anywhere between January and March of next year. Clayton Glass have stated in a short video interview, which you can see further below, that theirs will be available from July 2026.

Regency Glass have partnered with Corning Incorporated, which is a glass and tech giant in the US. You’re likely to be reading this article via a Corning glass product. They are the company behind Gorilla® Glass, which is the glass used on billions of smartphones and other devices around the world. However, it is their Enlighten™ Glass, which is a technology that has been around in various iterations since the 1960s, that is used as the razor-thin centre pane in the Regency Triple product. The 1.6mm centre-pane product appears to be a UK-developed innovation from Clayton Glass – something which will become clearer the more that is known about the product.

Thermal performance is not yet known for both products, but I think it is safe to assume that U-values for both are going to be lower than regular double-glazed units and perhaps triple-glazed ones as well. I welcome comments from Regency and Clayton in the section below if they want to elaborate further.

In terms of weight performance, Regency Triple appears to be the frontrunner, with a 30% reduction in weight compared to conventional triple-glazed units. Cost uplifts for these products are not yet known either. But again, we can assume that they are going to cost more than regular DGUs.

What the companies say

Both companies have released videos on their new thin triple-glazed products. Regency have also published an article which expands further on their new product and partnership with Corning:

Regency Glass

Additional information provided by Regency Glass:

The company will introduce the “Regency Triple” featuring Corning® Enlighten™ Glass in early 2026.

Regency Glass Ltd, in collaboration with Corning Incorporated, one of the world’s leading innovators in glass, ceramics, and materials science, will soon launch its highly anticipated, next-generation triple-glazed unit: Regency Triple featuring Corning® Enlighten™ Glass. This revolutionary product is set to launch in Q1 2026, and today marks the first time its name is shared publicly.

At the heart of the Regency Triple lies an innovation not yet seen in the UK market: a 0.5mm piece of Corning® Enlighten™ Glass. The collaboration between Regency Glass and Corning brings to life an ultra-thin glass triple-glazed unit that delivers all the performance of a traditional triple-glazed unit without the bulk, weight, or compromise.

What makes the Regency Triple different?

The Regency Triple is not just another triple-glazed unit; it is a leap forward in insulated-glass unit (IGU) technology, offering real-world benefits across fabrication, installation, and performance, including:

- Ultra-thin profile: Provides the benefits of triple glazing whilst fitting seamlessly into a 28mm cavity, making the Regency Triple an ideal solution for the replacement window market.

- Lightweight design: Features a 30% decrease from conventional triple-glazed units and only a 5% weight increase compared to conventional double-glazed units, making product handling easier for installation teams.

- Enhanced thermal performance: Delivers impressively strong thermal insulation, helping homeowners improve energy efficiency without costly or bulky frame modifications.

- Design flexibility: Offers custom cavity widths available to suit any specification due to the use of a Thermo Plastic Spacer bar, also known as TPS®.

- Thermal durability without tempering: Corning® Enlighten™ Glass delivers high thermal durability, offering protection from field thermal breakage.

READ FULL ARTICLE HERE: https://www.regencyglass.co.uk/our-next-generation-tgu-regency-triple-featuring-corning-enlighten-glass/

Clayton Glass

READ LINKEDIN CLAYTON GLASS POST HERE: https://www.linkedin.com/feed/update/urn:li:activity:7381267035747532800/

Big potential

Some of the biggest barriers to traditional triple-glazed units have been excessive weight, storage, pressure on hardware and installers, amongst other things. But if we are looking at triple-glazed units that are 30% lighter, can achieve U-values that reach or surpass current Building Regulation requirements, that can fit into 28mm cavities across all profiles, which puts less strain on installers and fabricators alike, then we have products which look like they could have huge potential.

On the surface, both these products appear to solve problems that our industry has chewed over for some time. Obviously, there is more to be discovered about these products. We do not know their official U-values and cost. Once we do, we’ll have a better understanding of the potential of these products.

In his video interview, Clayon Glass Director Ryan Green thought it could take 5-10 years for this product to take off properly. I think that is a slightly conservative estimate, perhaps intentionally. If these products can nail solid U-values, or perhaps even better than what we can achieve now, and is at a price-point that doesn’t make the product prohibitive to installers and consumers, then I think we could be looking at a new glass technology that is going to be in high-demand.

In a LinkedIn post about this subject, there were a number of other questions that were posed by DGB followers. Size limitations were one point that was raised, another being questions around handling and processing, max sizes, etc. All of these, I am sure, will be answered as more information is provided.

I will continue to follow the progress of both these products over the coming months. I am eager to see how it is going to transform the triple-glazed market and fenestration as a whole.

Subscribe for FREE below to receive the weekly DGBulletin newsletter and monthly digital magazine!