Innovations in the glass sector always continue to amaze me. Out of all the facets which make up the fenestration sector, glass is perhaps the most advanced right now. That advancement continues with the announcement that the University College London (UCL) and EPSRC (Engineering and Physical Sciences Research Council) have developed a new smart window incorporating nano-structures, inspired by nature.

“No more cleaning windows”

Here is how the UCL explains the new product and it’s many benefits:

The windows use nature inspired nanostructures which mimic the eyes of moths to cut glare, save energy and clean themselves. The prototype glass was developed with support from the Engineering and Physical Sciences Research Council (EPSRC) and tests confirm it delivers three key benefits:

· Self-cleaning: The window is ultra-resistant to water, so rain hitting the outside forms spherical droplets that roll easily over the surface – picking up dirt, dust and other contaminants and carrying them away. This is due to the pencil-like, conical design of nanostructures engraved onto the glass, trapping air and ensuring only a tiny amount of water comes into contact with the surface. This is different from normal glass, where raindrops cling to the surface, slide down more slowly and leave marks behind.

· Energy-saving: The glass is coated with a very thin (5-10 nanometre) film of vanadium dioxide which during cold periods stops thermal radiation escaping and so prevents heat loss; during hot periods it prevents infrared radiation from the sun entering the building. Vanadium dioxide is a cheap and abundant material, combining with the thinness of the coating to offer real cost and sustainability advantages over silver/gold-based and other coatings used by current energy-saving windows.

· Anti-glare: The design of the nanostructures also gives the windows the same anti-reflective properties found in the eyes of moths and other creatures that have evolved to hide from predators. It cuts the amount of light reflected internally in a room to less than 5% – compared with the 20-30% achieved by other prototype vanadium dioxide-coated energy-saving windows – with this reduction in ‘glare’ providing a big boost to occupant comfort.

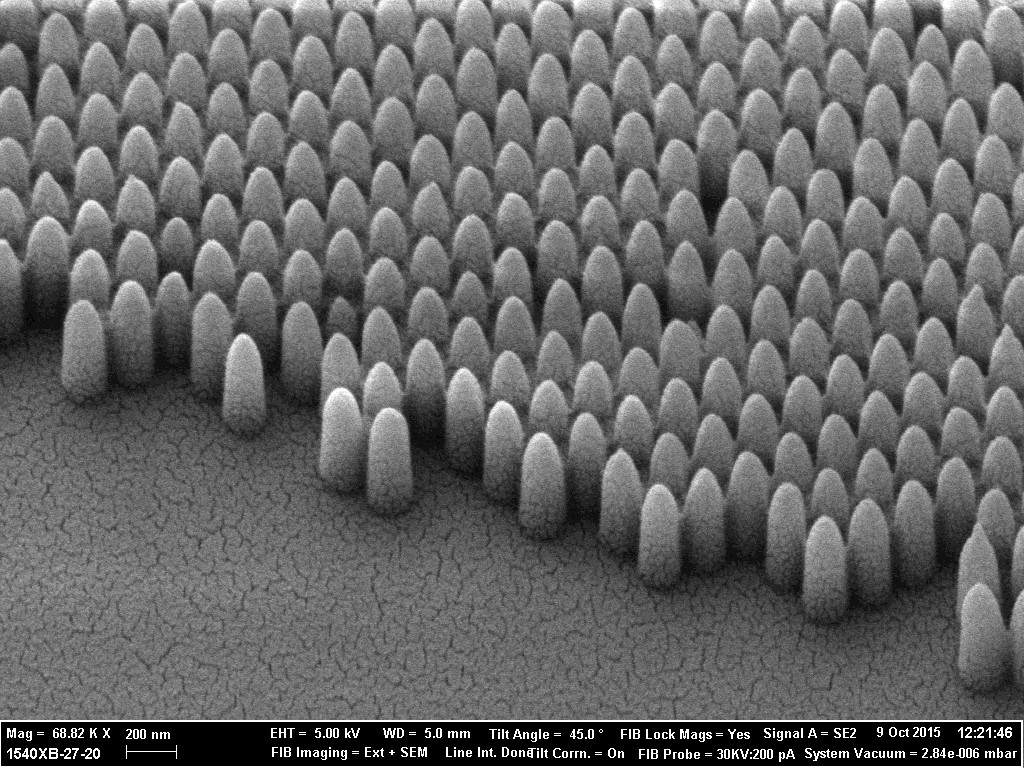

A scanning electron miscroscope photograph shows the pyramid-like nanostructures engraved onto glass, at 200 nm they are 100 times smaller than a human hair.. Controlling the surface morphology at the nanoscale allows scientists us to tailor how the glass interacts with liquids and light with high precision.

Project leader, Dr Ioannis Papakonstantinou (UCL Electronic & Electrical Engineering), said: “This is the first time that a nanostructure has been combined with a thermochromic coating. The bio-inspired nanostructure amplifies the thermochromics properties of the coating and the net result is a self-cleaning, highly performing smart window.”

The team calculate that the windows could result in a reduction in heating bills of up to 40%, with the precise amount in any particular case depending on the exact latitude of the building where they are incorporated. Windows made of the ground-breaking glass could be especially well-suited to use in high-rise office buildings.

Dr Papakonstantinou, explained: “It’s currently estimated that, because of the obvious difficulties involved, the cost of cleaning a skyscraper’s windows in its first 5 years is the same as the original cost of installing them. Our glass could drastically cut this expenditure, quite apart from the appeal of lower energy bills and improved occupant productivity thanks to less glare. As the trend in architecture continues towards the inclusion of more glass, it’s vital that windows are as low-maintenance as possible.”

Professor Ivan Parkin (UCL Chemistry), said: “We are currently in discussions with UK manufacturers with the aim of driving this new window concept through to commercialisation. The key to this will be scaling up the nano-manufacturing methods we have developed to produce the glass, as well as the process of coating it in vanadium dioxide.”

Smart windows could begin to reach the market within around 3-5 years, depending on the team’s success in securing industrial interest. A 5-year European Research Council (ERC) starting grant (IntelGlazing) has been awarded to the UCL team to develop smart windows on a large scale and test them under realistic, outdoor environmental conditions.

A smart glass prototype developed by the UCL team. The dark areas are decorated with the nanostructures, which significantly suppress reflections. They also repel water forcing it to form nearly spherical droplets and preventing it from wetting the surface of the glass. The UCL logo is made of untreated glass and appears significantly more reflective compared with its surrounding region.

PhD student and lead researcher, Alaric Taylor (UCL Electronic & Electrical Engineering), added: “In addition to developing the glass, we hope to create a ‘smart’ film that incorporates our nanostructures and can easily be applied to conventional windows using a DIY approach. We’d develop it so the film still delivers the same benefits as the glass without significantly affecting aesthetics.”

Professor Philip Nelson, Chief Executive of EPSRC, said: “This project is an example of how investing in excellent research drives innovation to produce tangible benefits. In this case the new technique could deliver both energy savings and cost reductions.”

Read the UCL article

Read the EPSRC article

I am conscious that there have been a number of false dawns in glass that have promised many things but have yet to make it to mass market. This new product however I believe could be the one to finally crack that nut.

The article above talks about commercial applications, specifically in skyscrapers. There is no doubting that every mega-tall building in the world could benefit from glass like this. Imagine how easy they would become to keep clean and to keep temperatures and glare under control.

But I believe that if they can get mass-manufacture right and come to a sensible pricing point then this could become a genuine product option in the UK residential sector too.

I would urge the major companies in glass, the likes of Saint-Gobain, Pilkington and Guardian to plough investment into this new opportunity. It could transform the glass sector around the world.

Probably a very long time from our market and has a massive disadvantage …..

QUOTE ……….”.Energy saving ……….it prevents infrared radiation from the sun entering the building”

That means the end to A rated windows , so the science behind the new glass obviously isn’t good enough for the UK window market which is already producing windows that provide more heat than they lose.*

* based on spurious Everest Claims and a lack of will of the BFRC to do anything about it !