Steel right now is expensive. Very expensive. To give you an idea as to how much the cost of steel has risen over the past year or so…

April 2020:

May 2021:

In percentage terms, the cost of steel per ton in the space of a year has risen 113%. At the time of writing the current cost per ton has eased back only slightly to $722.5 per ton.

Around the world, the cost of commodities has skyrocketed as the global economy opens up and countries plough money into construction, infrastructure and home improvements. For example, the cost of lumber in the US rose over 200% in a short space of time due to shortages and not enough suppliers able to keep up with demand. Whilst there has been a sharp pullback and some joy at that, it doesn’t really make much of a difference. Steel is consumed by so much around the world, which is why this is the commodity that matters. The fact that the cost of timber in America has come back down doesn’t make all that much of a difference to anything.

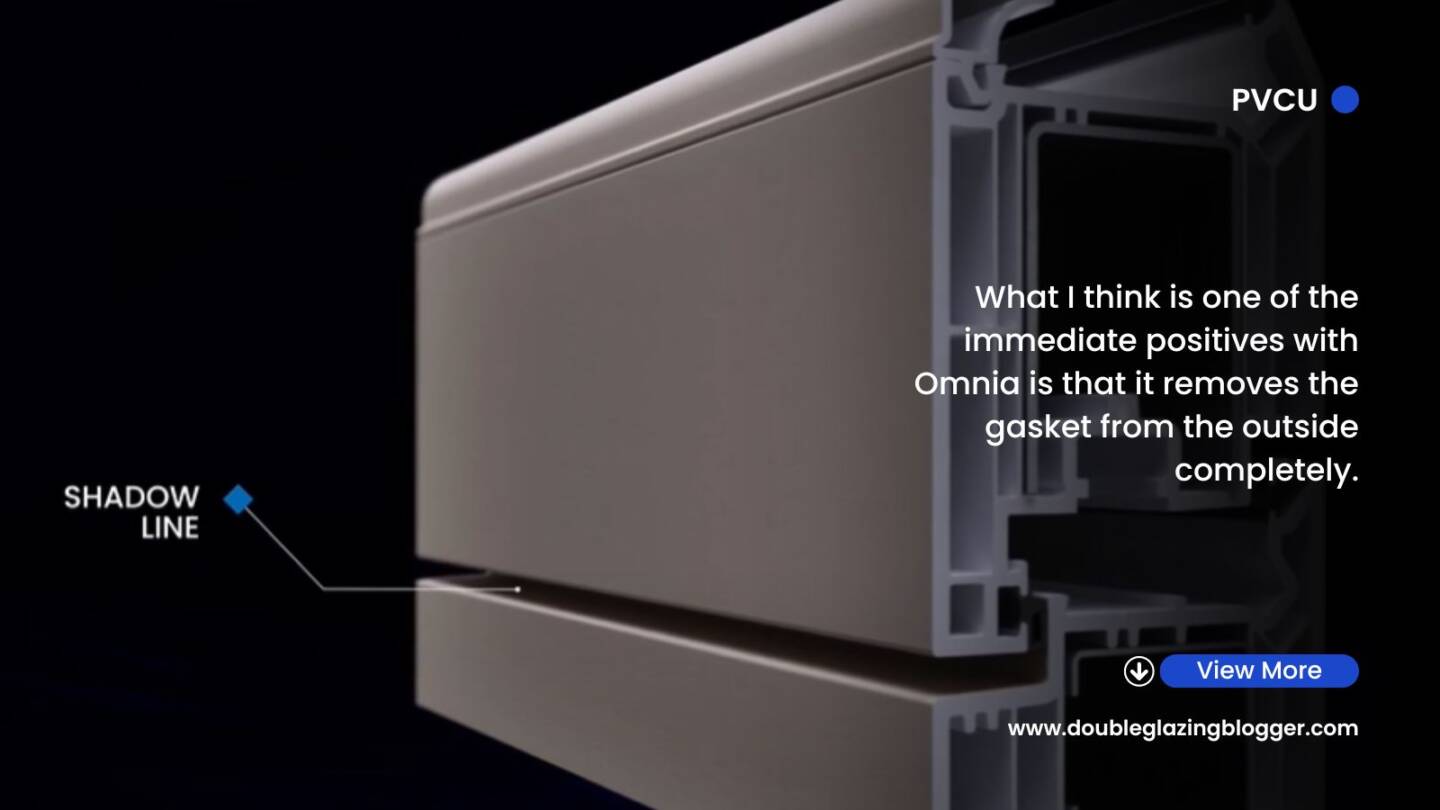

For UK fenestration, steel is a vital component to the reinforcing of many PVCu products and has been for a long time. However, the rapidly rising cost of steel has been one of the many contributing factors to our own rapidly rising costs in our own sector. Supply has also become strained as global politics and red-hot economies snap the material up at record rates.

At this moment of reflection for UK fenestration, will it be forced to look at alternatives to steel?

Will steel still play a part?

I found it interesting to read at the end of June that sales of Window Widget’s Webar product have surged:

With supplies of steel across all manufacturing sectors still not yet stabilised from an availability perspective along with several price hikes, Window Widgets have experienced a surge in demand for Werbar, which is their dedicated range of RCM reinforcement sections for PVCu window and door systems.

As companies have found it difficult and vastly more expensive to secure steel reinforcement, it appears a significant number have already been looking at alternative forms of reinforcement for their product. Whether these companies will return to using steel once prices and supply become more stable remains to be seen. But as is often the case, if you change habits for long enough, they tend to stick. Some may decide to stick with Werbar due to the price advantage and more stable supply.

How long this trend lasts will depend on how long high prices stay and how readily available steel is going to be. There is a general thinking that high prices are here to stay. With consumers seemingly able to swallow up higher prices there is little motivation to let prices return back to levels seen in early 2020. Demand also looks set to stay high as the major nations across the planet invest heavily in infrastructure projects and global consumption continues to rise.

This does pose a question for our sector. For decades our industry has used steel to add strength to PVCu products and it has been used as a USP for fabricators and installers. But should rising steel prices and questions over supply continue, some manufacturers and indeed systems companies may feel the need to look at alternatives on a more permanent basis.

Switching over to alternative materials however isn’t that simple. Many PVCu systems in the market have been designed and tested using steel reinforcement within the products. There are products out there designed to meet certain standards and criteria using specifically steel. It would not be that simple to just ditch steel and use something else. There would be a process to follow and that takes time and money. Whether systems companies are already looking at the 5-10 year journey and pondering alternative methods of reinforcing in the future remains to be seen. But for the immediate and medium-term, steel is still here to stay.

Environmental impacts

Steel production is not the cleanest process in the world. For every ton of steel produced, 1.85 tons of carbon is produced. According to carbonclean.com, if steel production was a nation, it would be the 5th worst polluter on the planet. Not a great stat for the sector, and one that needs to be rapidly improved as the planet moves quickly to a zero-carbon future.

There are solutions, however. Carbon capture storage solutions for steel factories are becoming more mainstream, and the results are very positive. But the technology needs to be adopted across the world at speed to bring carbon emissions down enough so that there isn’t a big push back against the sector.

From a fenestration perspective that is slowly moving towards a carbon-neutral future, it’s probably not going to land on our radar all that quickly. Our apathy and lethargy towards change unless it’s absolutely immediate means we’ll likely not scrutinise the production practises of steel for a while. Maybe never.

Recycling though is where steel use is redeemed. Steel is 100% recyclable, which means any and all steel in use now can be used over and over again. Like PVCu, the more post-consumer steel we can reintroduce into the fenestration sector supply chain the better it would be for the environment and ensure a more secure supply of the material.

Overall, I do not see steel being dropped from UK fenestration any time soon. I do think more companies will start to look at alternatives though, like Werbar, as some seek to cut costs and secure a more reliable supply of reinforcing material. I think over the next few years we’ll see a more varied and diversified menu of options when it comes to how our products are reinforced, steel remaining one of the popular options.

To get weekly updates from DGB sent to your inbox, enter your email address in the space below to subscribe:

By subscribing you agree to DGB sending you weekly email updates with all published content on this website, as well as any major updates to the services being run on DGB. Your data is never passed on to third parties or used by external advertising companies. Your data is protected and stored on secure servers run by Fivenines UK Ltd.