For clarity, this post refers to businesses that both fabricate and install windows and doors.

Threat of trade counters

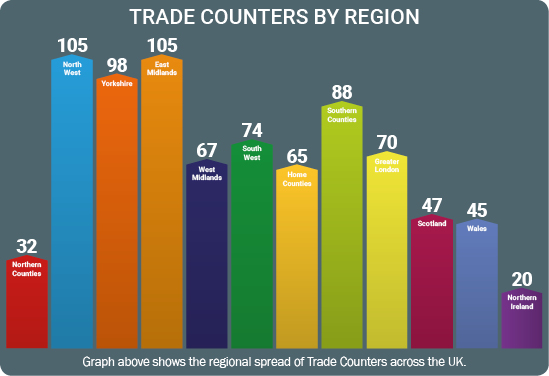

Small installer and fabricator businesses have been squeezed from a few areas in recent years. The economy has been one of them, but I’ll talk about that in a second. But one of the major changes in industry has been the rise of trade counters. Just take a look at this graph from the 2014 Insight Data Market Report:

The trade counter sector of our industry is one which is in rude health. It’s gone from strength to strength in the last few years, with fabricators spotting the gap for DIY-ers and trades people wanting to have access to every day window and door products.

But this also means they have been eating away into those installer/fabricator businesses that also sold to trade. Dedicated trade counters have made it very easy for people to walk in, ask for something, and walk away with it almost immediately. After the initial success of these trade counters, I can only seem them growing in the years to come.

Economy and costs

It’s no secret that costs in our industry have risen quite steeply in the past few years. We’re expecting an increase in PVCu prices in fact in the coming months. For a small fabrication and installation business, these price increases might have hurt a little more than normal.

Each time a cost goes up at the top of the chain, it filters down to installers, and those who fabricate as well. Except for companies producing only a few frames per week, these costs are more significant than to a larger fabricator who lets say pumps out 2000 frames per week. The bigger the company, the easier the costs can either be absorbed, or watered down before they are passed on to installers.

Innovation from larger fabricators

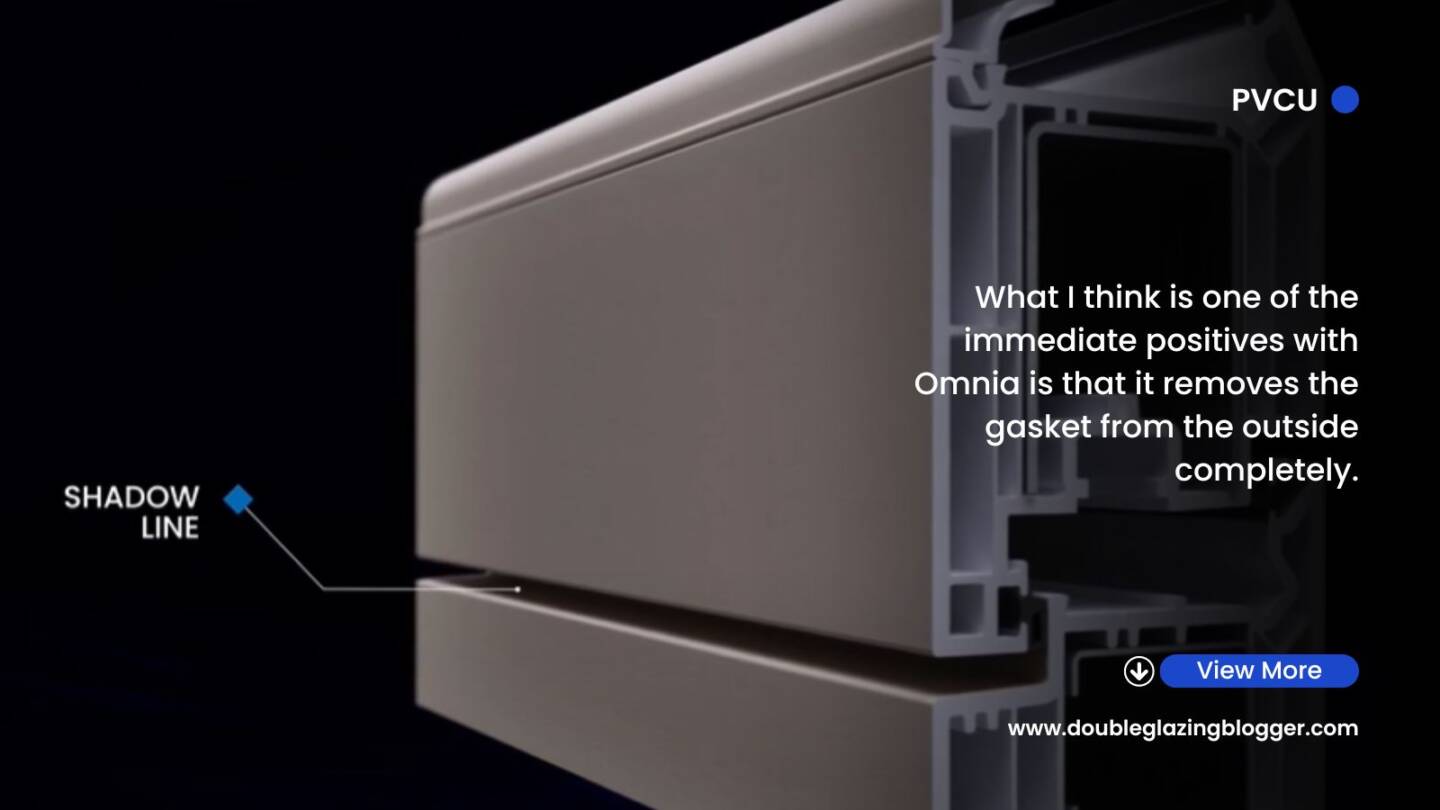

The last few years has probably been the most innovative and forward thinking period in our industry for a while. Quite regularly now we see either brand new products or extensions to existing product ranges, expanding the number of great window and door products out there. A lot of this has been driven by the large R&D budgets by the syscos and larger fabricators. The companies with the time, money and people to turn ideas in reality.

However the installer/fabricators making less that 100 frames per week don’t have those resources, and so continue to fall behind more of the forward thinkers. That’s not necessarily their fault. There will always be companies that have more cash to spend on things like that. But it does mean that the smaller installer/fabricators have to rely on their sysco to do the forward thinking for them, which of course does not always happen.

So for these reasons, it’s easy to see that an installer/fabricator producing 30-40 frames per week might be be as profitable as it once might have been. There is an argument which says it would be easier for those smaller installation and fabrication businesses to relieve some of the pressure on themselves and focus just on installation and buy in products from bigger, dedicated fabricators. It could make them more profitable, reduce costs etc. They could even sell on existing machinery and make a few quid too. Fabricating and installing a couple of dozen frames per week just does not seem profitable long term to me any more.

As always, all comments welcome via the section below. Are you a small installer/fabricator? Have things become tougher over the last few years? Would you consider dropping the fabricating side and focus purely on installation? I’d like to hear your views on this, whether you agree or disagree.

Why the glazing industry needs small fabricators \ installers Many years ago most towns had a baker, butcher and a glazier etc. Who employed local people who spent their earnings with other local businesses and so the town grew and generated local wealth and employment. Moving on double glazing meant investment in machinery and lead times as we could no longer offer product whilst customer waited. The glazier became a sealed unit manufacturer. Then aluminium followed by PVCu frames these profile manufacturers required local businesses to sell their products and system company number One sold to glazier number One. Then… Read more »

We’re a micro fabricator and installer with over 28 years of trading under our belts. We’ve seen bigger companies rise and fall yet we’re still here and as for innovation, well just ask Veka, we’re helping push our profile system forward, constantly coming up with new ideas, some of which are in production now and will be ready for those big fabricators to use some time next year. Don’t write us little companies off. We can adapt quicker than the big boys. Yeah OK we haven’t got their marketing budget or their R&D budget but so what we’re still better… Read more »